MH Super 114

Weight : 320 lbs

Certification: CE/ NSF

- Stock Availability: Austin, TX

- It allows burgers of up to 5.10 inches in diameter and 1 inch thick. Thereafter the portions can be conveniently flattened with the roller up to 5.90 inches in diameter

- Production of up to 3,600 patties or 6,000 meatballs

- Fully automatic patty maker

- Automatic paper application for burgers with diameter between 3.15-4.50 inches

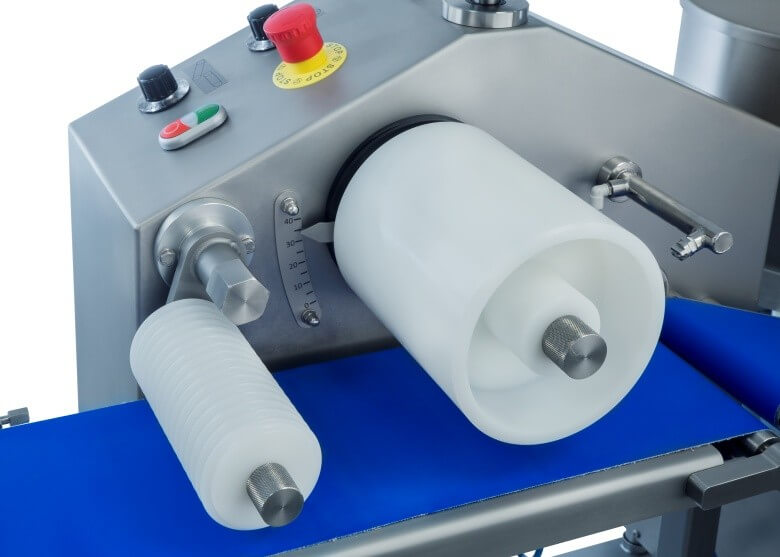

- Second roller to make grill marks on the product

- Continuous water sprayer on the conveyor belts and on the roller

Warranty

1 Year Standard Warranty

Financing Available

Orders Over $500

MH Super 114

30% faster than our 100A, same easy to use technology for use in any kitchen with additional mobility

Industrial Speed and Efficiency with Low Energy and Noise

1. Speed And Production Controls

Take full control of your production process with our advanced speed controls, allowing you to customize the pace of both the portioner and outfeed belt. Whether you need to speed up for high-demand periods or slow down for delicate operations, our intuitive speed controls provide the flexibility to optimize efficiency and ensure seamless integration within your workflow.

2. Perfect Product Customization

Achieve perfection in product thickness and appearance with our precision-engineered adjustment lever. Designed to dial in the ideal thickness and enhance the look and feel of your products, this intuitive lever puts you in complete control, allowing for fine-tuned adjustments that meet your exact specifications and elevate the overall quality of your offerings.

3. Water Enhancement

Enhance the performance of your machine with our specialized water line addition, specifically designed to optimize the handling of sticky or tacky products. This innovative feature ensures smoother product flow and reduces adhesion enabling you to maintain consistent production and maximize efficiency even with challenging product.

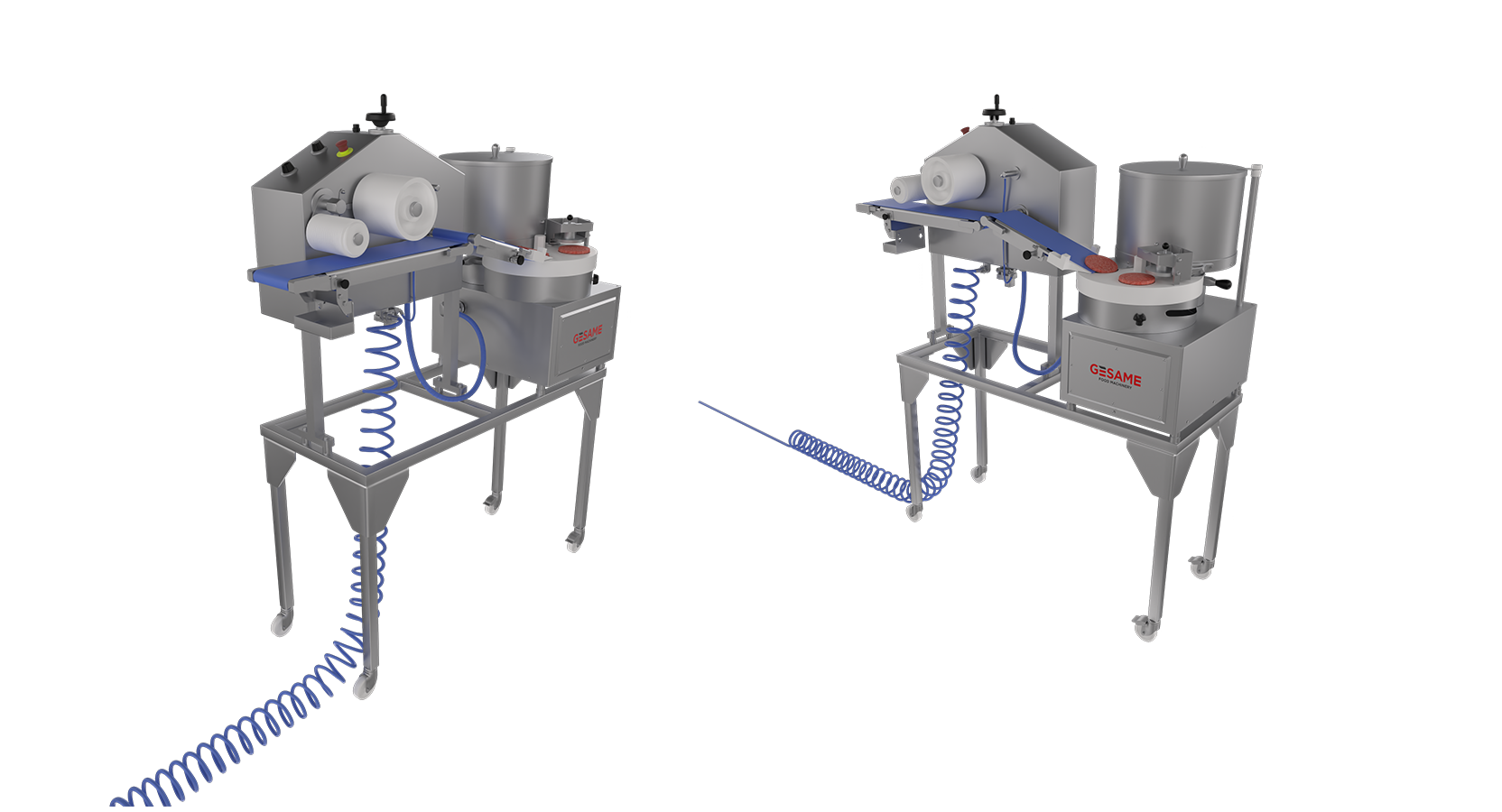

4. Robust Product Hopper

Introducing our robust product hopper, designed to handle large volumes with ease. Its spacious capacity holds up to 50 pounds of product and ensures uninterrupted production, allowing for efficient and continuous workflow.

5. Cutting Edge Safety Sensors

Introducing our cutting-edge magnetic safety sensor technology. A reliable and versatile solution that ensures the utmost safety in a wide range of applications. You and your staff can experience the latest in safety technology.

6. Time Saving Paper Applicator

Discover the game-changing optional paper applicator that streamlines your workflow, saving you valuable time and money. Its seamless integration with our equipment ensures precise and efficient paper application between patties thus reducing waste, maximizing productivity and perfectly separating your portions.

7. Effortless Portion Control

Take control of portion precision with our innovative portion controls. Designed to accurately measure and dispense precise amounts, they empower you to minimize waste, maintain consistent serving sizes, and maximize cost efficiency for your business.

8. Convenient Caster Wheels

Effortless mobility in your kitchen with our convenient caster wheels, designed to glide your machine across any surface. These sturdy and reliable wheels enable easy maneuverability, allowing you to position and relocate the machine as needed, ensuring optimal workflow and flexibility in your kitchen setup.

1. Speed And Production Controls

Take full control of your production process with our advanced speed controls, allowing you to customize the pace of both the portioner and outfeed belt. Whether you need to speed up for high-demand periods or slow down for delicate operations, our intuitive speed controls provide the flexibility to optimize efficiency and ensure seamless integration within your workflow.

2. Perfect Product Customization

Achieve perfection in product thickness and appearance with our precision-engineered adjustment lever. Designed to dial in the ideal thickness and enhance the look and feel of your products, this intuitive lever puts you in complete control, allowing for fine-tuned adjustments that meet your exact specifications and elevate the overall quality of your offerings.

3. Water Enhancement

Enhance the performance of your machine with our specialized water line addition, specifically designed to optimize the handling of sticky or tacky products. This innovative feature ensures smoother product flow and reduces adhesion enabling you to maintain consistent production and maximize efficiency even with challenging products.

4. Robust Product Hopper

Introducing our robust product hopper, designed to handle large volumes with ease. Its spacious capacity holds up to 50 pounds of product and ensures uninterrupted production, allowing for efficient and continuous workflow.

5. Cutting Edge Safety Sensors

Introducing our cutting-edge magnetic safety sensor technology. A reliable and versatile solution that ensures the utmost safety in a wide range of applications. You and your staff can experience the latest in safety technology.

7. Time Saving Paper Applicator

Discover the game-changing optional paper applicator that streamlines your workflow, saving you valuable time and money. Its seamless integration with our equipment ensures precise and efficient paper application between patties thus reducing waste, maximizing productivity and perfectly separating your portions.

7. Effortless Portion Control

Take control of portion precision with our innovative portion controls. Designed to accurately measure and dispense precise amounts, they empower you to minimize waste, maintain consistent serving sizes, and maximize cost efficiency for your business.

8. Convenient Caster Wheels

Effortless mobility in your kitchen with our convenient caster wheels, designed to glide your machine across any surface. These sturdy and reliable wheels enable easy maneuverability, allowing you to position and relocate the machine as needed, ensuring optimal workflow and flexibility in your kitchen setup.

Forming Plate Shapes Suitable For Most Applications

At the heart of our patty forming machine's exceptional performance lies our top-of-the-line forming plates. Made from durable and food-safe materials, these plates have been meticulously engineered to withstand the rigors of daily use, while consistently delivering precise and consistent results. What sets our forming plates apart from the competition is their ability to maintain their shape and structure even after repeated use, ensuring that each and every patty comes out with the same level of perfection as the last. Understanding that every business has its unique needs, we at Gesame Food Machinery are proud to offer custom or irregular molding plates to accommodate even the most specialized products. Are you looking to add delicious chicken nuggets to your menu? Our team of expert engineers can create tailor-made mold plates that will flawlessly produce the desired shape and size for your nuggets, all while maintaining the same high quality and precision that our standard forming plates provide.

Our commitment to quality and innovation goes beyond just our forming plates. We strive to ensure that every aspect of our patty forming machine is built with the same level of care and attention to detail. From the intuitive and user-friendly interface, designed to make operation a breeze for even the most novice users, to the easy-to-clean components that help maintain the highest levels of hygiene and food safety, we've thought of everything to make your food production experience seamless and enjoyable.